News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > News

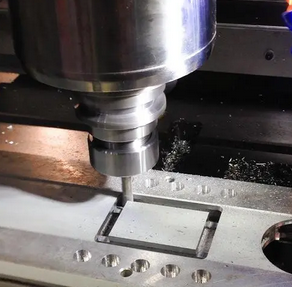

What are the main points of CNC milling process and operation?

Add Time:2025-03-28

Process introduction

A common metal cold working method, and turning is different in the milling processing tool under the spindle drive high-speed rotation, and the workpiece to be machined in relative rest.

The difference between turning and milling:

Turning is used to process rotary parts, the parts are clamped on the machine tool spindle through the three-grip chuck, and high-speed rotation, and then use the turning tool according to the bus bar of the rotary body to cut out the product shape. The lathe can also be used for inner hole, thread, bite, etc., the latter two are low-speed processing.

First, the contour of the curve on the workpiece, straight line, arc, thread or spiral curve, especially the contour of the non-circular curve and the list curve given by the mathematical expression.

Second, the spatial curve or surface of the mathematical model has been given.

Third, although the shape is simple, the size is large and the detection is difficult.

Fourth, the inner cavity and the interior of the box that are difficult to observe, control and detect when processed with ordinary machine tools.

Fifth, holes or planes with strict dimensional requirements.

sixth, a simple surface or shape that can be processed in a single clip.

seventy, the use of CNC milling processing can effectively improve productivity and reduce labor intensity of the general processing content.

The main processing objects suitable for CNC milling are the following categories: plane contour parts, variable bevel parts, space surface contour parts, holes and threads.

Operating essentials

First, the operator should wear tight work clothes, cuffs tight; Wear protective hats; Wear protective goggles when milling at high speed; Wear a mask when milling cast iron; When operating, it is strictly forbidden to wear gloves to prevent the hand from getting involved between the rotating tool and the workpiece.

Second, before the operation should check the milling machine components and safety devices are safe and reliable; Check whether the safety and reliability of the electrical parts of the equipment are good.

Third. When loading and unloading the workpiece, the workbench should be retreated to a safe position. When using the wrench to tighten the workpiece, the direction of force should avoid the milling cutter to prevent the wrench from sliding into the tool or fixture.

Fourth. When installing and disassembling the milling cutter, use a special liner to pad it well, and do not hold the milling cutter directly by hand.

Fifth. When milling irregular workpieces and using vise, indexing head and special fixture to hold workpieces, the center of gravity of irregular workpieces and vise, indexing head and special fixture should be placed in the middle of the workbench as far as possible to avoid uneven stress on the workbench and deformation.

sixth, in the fast or automatic feed milling, do not go to the table to two extremes, so as not to crush the screw.

Seventh, when the machine is running, it is not allowed to adjust, measure the workpiece and change the lubrication method to prevent the hand from touching the tool and hurting the finger.

Eighth, in the milling cutter rotation is not completely stopped before, can not use the hand to brake.

Ninth, do not remove the chips by hand in milling, and do not blow with your mouth to prevent the chips from damaging the skin and eyes.

Tenth, in the motor fast feed, the handwheel clutch should be opened to prevent the fast rotation of the handwheel hurt.

Eleventh. When reversing the table, the reversing handle must be stopped in the middle position first, and then reversed, and no direct reversal is allowed.

Twelfth. When milling keyway shafts or cutting thin workpieces, avoid breaking the dividing head or working table.

Thirteenth, when milling the plane, it is necessary to use more than four cutter heads, choose the appropriate cutting amount to prevent the machine tool from vibration in milling.

Fourteenth. After work, stop the workbench in the middle position, and the lifting platform falls to the lowest position.

Fifteenth, for the CNC vertical milling machine, the work should be pre-selected according to the process requirements related to the work procedure, spindle speed, tool feed, tool movement trajectory and continuous offside. Put the electrical knob in the "alignment" position for test, confirm that there is no problem, and then put the electrical knob in the automatic or semi-automatic position for work.