- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

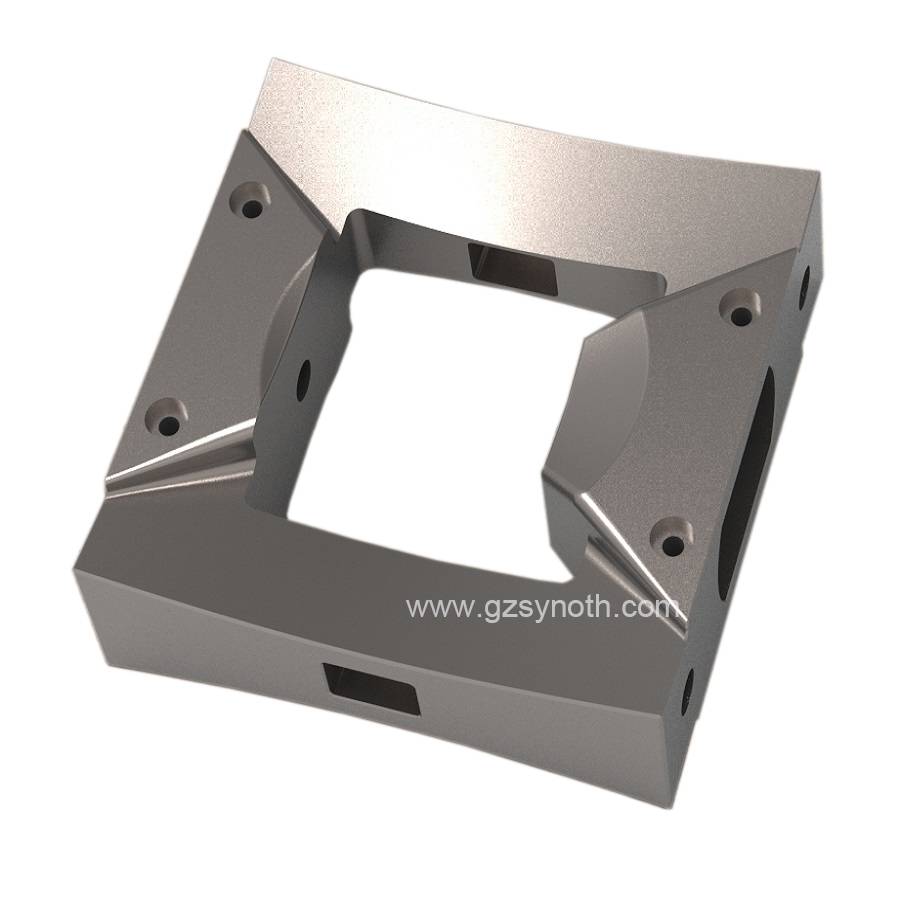

First,optimize the processing technology:select the appropriate clamping surface and evenly distribute the clamping force to avoid applying too much force in the position that is easy to cause deformation. When clamping forces are used in multiple directions, attention should be paid to the order of clamping, first making the workpiece and the support contact the clamping force, and then applying the main clamping force to balance the cutting force.

Reasonable choice of tool :For the processing of aluminum alloy, choosing the right tool Angle is very important. High-speed tools and carbide tools are usually used for machining to reduce friction and reduce the cutting temperature during the cutting process, thereby preventing part deformation.

Use of cutting fluid :The reasonable use of special cutting fluid with appropriate concentration can improve the tool durability and machining surface quality, and reduce the deformation of aluminum alloy parts under the CNC machining center machine tool.

Aging treatment or heat treatment :for deformable parts such as aluminum alloy thin-walled cavity, aging treatment or heat treatment can be carried out after rough machining to eliminate internal stress, and then finish machining to avoid deformation.

Adjust the position of the feed block :for CNC wire cutting, by adjusting the position of the feed block, reduce the probability of broken wire, improve the processing efficiency and quality. For example, the position of the feed block is rotated after every 8 hours of processing to reduce wire breakage and processing costs and improve economic efficiency.

Through the above measures, can effectively prevent and solve the damage risk of aluminum alloy parts in CNC machining, improve the processing quality and efficiency .