News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > Industry information

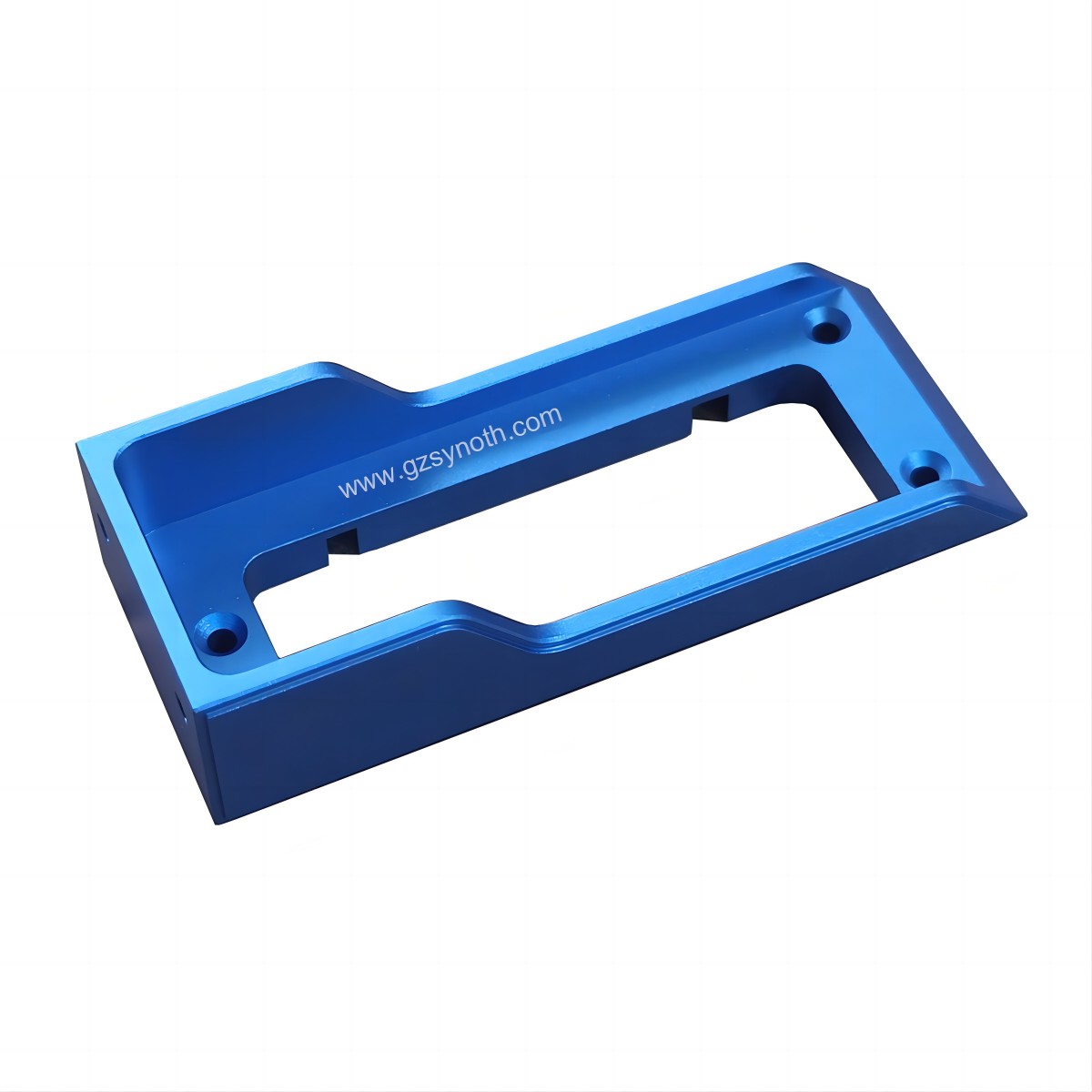

CNC machining camera accessories, the perfect evolution of photographic equipment

Add Time:2025-03-28

The Perfect Evolution of Photography Equipment: CNC Machining for Camera Accessories

In the ever-evolving world of photography, the demand for precision, durability, and innovation has never been higher. As photographers push the boundaries of creativity, the tools they rely on must keep pace. Enter CNC (Computer Numerical Control) machining—a technology that has revolutionized the production of camera accessories, ensuring that photography equipment evolves to meet the needs of modern professionals and enthusiasts alike.

CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools. This technology allows for the creation of highly precise and complex parts, making it ideal for producing camera accessories that require exact specifications and superior quality.

Precision and Customization

Precision and Customization

One of the most significant advantages of CNC machining is its ability to produce parts with exceptional precision. Camera accessories such as lens mounts, tripod heads, and camera cages must fit perfectly to ensure optimal performance. CNC machining achieves this by following detailed digital blueprints, resulting in components that are accurate to within micrometers.

Moreover, CNC machining allows for a high degree of customization. Photographers often have unique needs based on their shooting style and subject matter. Whether it's a custom grip for better handling or a specialized bracket for mounting additional equipment, CNC machining can create bespoke solutions that enhance the photographic experience.

Durability and Material Excellence

Photography equipment is frequently subjected to harsh conditions, from extreme weather to rough handling. CNC machining enables the use of robust materials such as aluminum, titanium, and stainless steel, which offer superior strength and longevity. These materials are not only durable but also lightweight, ensuring that photographers can carry their gear without compromising on performance.

Innovation in Design

The flexibility of CNC machining encourages innovation in the design of camera accessories. Complex geometries and intricate details that were once impossible to achieve with traditional manufacturing methods are now within reach. This has led to the development of accessories that are not only functional but also aesthetically pleasing, blending seamlessly with the sleek designs of modern cameras.

Second. Camera Cages and Rigging: For videographers and filmmakers, camera cages provide a stable platform for mounting various accessories like microphones, monitors, and lights. CNC-machined cages offer a perfect fit and robust construction, essential for demanding shoots.

Third. Tripod Heads and Plates: Stability is key in photography, and CNC-machined tripod heads and plates provide the necessary rigidity and precision for sharp, blur-free images.

Fourth. Custom Grips and Handles: Ergonomics play a significant role in the comfort and usability of camera equipment. CNC machining allows for the creation of custom grips and handles tailored to the photographer's hand, reducing fatigue during long shoots.

The Future of Photography Equipment

As technology continues to advance, the role of CNC machining in the production of camera accessories will only grow. The ability to produce high-quality, customized, and innovative components will drive the evolution of photography equipment, enabling photographers to capture the world in ways previously unimaginable.

In conclusion, CNC machining has become an indispensable tool in the creation of camera accessories, offering precision, durability, and innovation. As the photography industry continues to evolve, CNC machining will remain at the forefront, ensuring that photographers have the tools they need to push the boundaries of their art.

In the ever-evolving world of photography, the demand for precision, durability, and innovation has never been higher. As photographers push the boundaries of creativity, the tools they rely on must keep pace. Enter CNC (Computer Numerical Control) machining—a technology that has revolutionized the production of camera accessories, ensuring that photography equipment evolves to meet the needs of modern professionals and enthusiasts alike.

The Role of CNC Machining in Photography

CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools. This technology allows for the creation of highly precise and complex parts, making it ideal for producing camera accessories that require exact specifications and superior quality.

One of the most significant advantages of CNC machining is its ability to produce parts with exceptional precision. Camera accessories such as lens mounts, tripod heads, and camera cages must fit perfectly to ensure optimal performance. CNC machining achieves this by following detailed digital blueprints, resulting in components that are accurate to within micrometers.

Moreover, CNC machining allows for a high degree of customization. Photographers often have unique needs based on their shooting style and subject matter. Whether it's a custom grip for better handling or a specialized bracket for mounting additional equipment, CNC machining can create bespoke solutions that enhance the photographic experience.

Durability and Material Excellence

Photography equipment is frequently subjected to harsh conditions, from extreme weather to rough handling. CNC machining enables the use of robust materials such as aluminum, titanium, and stainless steel, which offer superior strength and longevity. These materials are not only durable but also lightweight, ensuring that photographers can carry their gear without compromising on performance.

Innovation in Design

The flexibility of CNC machining encourages innovation in the design of camera accessories. Complex geometries and intricate details that were once impossible to achieve with traditional manufacturing methods are now within reach. This has led to the development of accessories that are not only functional but also aesthetically pleasing, blending seamlessly with the sleek designs of modern cameras.

Examples of CNC-Machined Camera Accessories

First. Lens Adapters and Mounts: Precision is crucial when it comes to lens adapters and mounts. CNC machining ensures that these components fit perfectly, maintaining the optical alignment and integrity of the camera system.Second. Camera Cages and Rigging: For videographers and filmmakers, camera cages provide a stable platform for mounting various accessories like microphones, monitors, and lights. CNC-machined cages offer a perfect fit and robust construction, essential for demanding shoots.

Third. Tripod Heads and Plates: Stability is key in photography, and CNC-machined tripod heads and plates provide the necessary rigidity and precision for sharp, blur-free images.

Fourth. Custom Grips and Handles: Ergonomics play a significant role in the comfort and usability of camera equipment. CNC machining allows for the creation of custom grips and handles tailored to the photographer's hand, reducing fatigue during long shoots.

The Future of Photography Equipment

As technology continues to advance, the role of CNC machining in the production of camera accessories will only grow. The ability to produce high-quality, customized, and innovative components will drive the evolution of photography equipment, enabling photographers to capture the world in ways previously unimaginable.

In conclusion, CNC machining has become an indispensable tool in the creation of camera accessories, offering precision, durability, and innovation. As the photography industry continues to evolve, CNC machining will remain at the forefront, ensuring that photographers have the tools they need to push the boundaries of their art.