- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

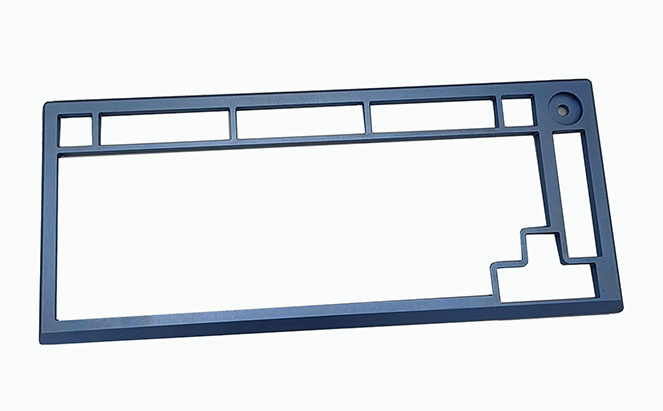

When CNC milling frame parts, key techniques include: Design a wide rounded radius to avoid sharp edges, use appropriate clamping methods to hold the material during machining, select the appropriate tool size according to the thickness of the frame, ensure the appropriate material support for the deep cavity, consider potential stress points and add reinforcement if necessary, and test cut the scrap before machining the final frame piece; At the same time, stiffness and stability are prioritized in the design to minimize vibration during machining.

The key points to remember as below:

First. Design considerations:

Rounded radius: Always use rounded corners to avoid stress points and facilitate tool access, especially on the inside corners.

Material support: If machining deep cavities, design sufficient material support to prevent potential breakage or deflection.

Reinforcement: Consider adding additional material to areas of high stress or bearing emphasis.

Clamping point: Design features such as T-slots or grooves clamp the workpiece firmly onto the CNC workbench.

Second. Tool selection:

Tool size: Choose a tool diameter suitable for frame thickness to maintain good stability and avoid excessive chip load.

Tool path strategy: Optimize tool paths for efficient material removal and minimize unnecessary cutting motion.

Third. Machining process:

Test cutting: Test cutting is always performed on scrap to verify tool selection, feed rate and depth of cut before machining the final frame.

Workpiece clamping: The workpiece is securely secured to the CNC workbench using appropriate clamping methods to minimize vibration. Cutting parameters: Adjust feed rate and cutting depth according to material type and desired surface finish.

Fourth. Material selection:

Rigidity: Select materials with high stiffness according to the application, such as aluminum alloy or steel, to resist deflection during processing.