- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

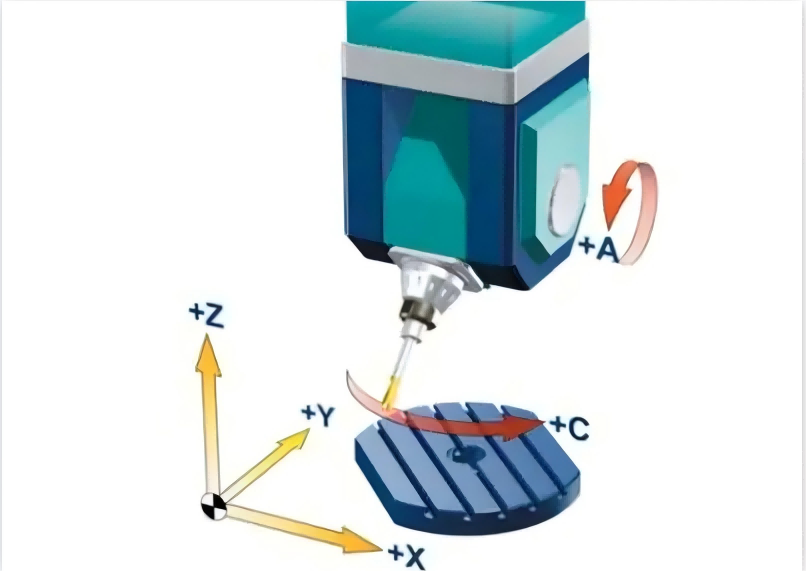

First. Ability to process complex parts: the five-axis linkage machining center has five coordinate axes, including three linear axes (X, Y, Z) and two rotating axes (A, C axis), which makes it able to cut and process in multiple directions, especially suitable for machining complex shape, surface and tilt Angle parts.

Second. Improve machining accuracy and efficiency: the five-axis linkage machining center can complete multiple surface machining by one-time clamping, avoiding repeated positioning error caused by multiple loading and entraining, and improving machining accuracy and efficiency. In addition, the production efficiency of the five-axis machining center is generally 3 to 5 times that of the ordinary machining center, which can cope with the processing needs of complex parts.

Third. Reduce equipment investment cost: five axis linkage machining center usually has a variety of functions, such as turning, milling and grinding, reducing the equipment investment cost and workshop area. In addition, the five-axis composite processing equipment reduces waiting time and improves production efficiency through intensive production.

Fourth. Meet the needs of a variety of industries: five-axis linkage machining center is widely used in aerospace, automotive, mold manufacturing and other fields, can meet the needs of these industries for complex shapes and high-precision machining.

Fifth. Reduce interference and tool position control: five-axis CNC technology through computer control and high-performance servo drive, can precisely control the tool position in the machining space, reduce interference problems, improve the stability and reliability of machining.

In summary, the five-axis linkage machining center is particularly suitable for the processing needs of special-shaped parts because of its complex motion ability and high precision and efficiency.