- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

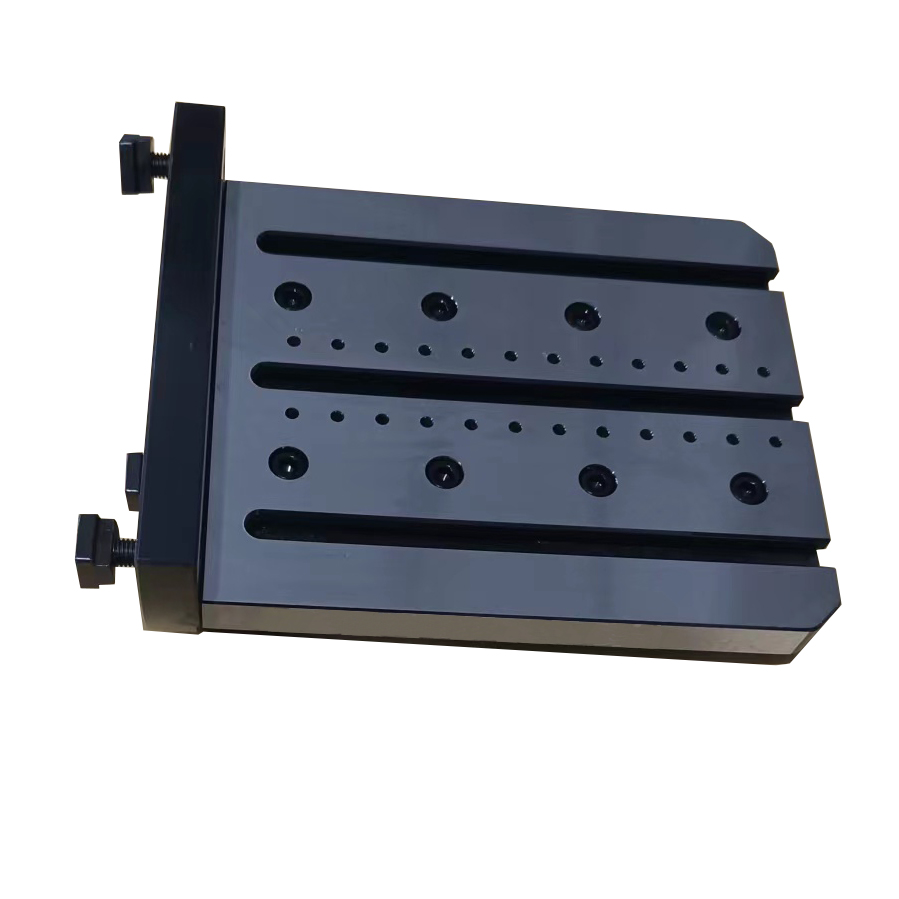

Precision parts processing in the specific application is definitely the higher the accuracy, the more exquisite it can reflect the processing level and quality, in addition, this kind of goods are more popular with customers, generally speaking, in the production of CNC machining center has not comparable advantages and characteristics, the product quality is generally higher, so what are the characteristics of precision parts processing?

First, the first CNC machine tool high precision mechanical parts processing efficiency is higher, CNC machine tool mechanical parts processing can also produce several surfaces, compared with general lathe processing can save a lot of process flow, save time, and CNC machining center out of the parts quality is relatively ordinary lathe to be much more stable.

Second, CNC machine tool high-precision mechanical parts processing in the development of new products has an irreplaceable effect, generally through programming can be different degrees of complexity of mechanical parts processing ah, and modification and update design only need to change the process of the lathe, which can greatly shorten the product development cycle.

Third, CNC machine tool high precision mechanical parts processing automation degree is very enough, greatly reduce the physical labor intensity of workers, workers in the processing process does not need to be like ordinary lathe as the whole control, mainly the lathe observation and supervision. However, the technical content of the corresponding CNC machining center is higher than that of ordinary lathes, so it requires higher mental labor than ordinary lathes.

Fourth. The initial investment is relatively large compared to ordinary lathes, because the price of CNC lathes is very high, and its maintenance costs and the first production preparation period are long.