News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > Industry information

Electropolishing vs Mechanical Polishing: Surface Finish Quality

Add Time:2025-08-12

When comparing electropolishing and mechanical polishing in terms of surface finish quality, the key differences lie in smoothness uniformity, microstructural integrity, resistance to defects, and functional performance. Here’s a detailed breakdown of how they stack up:

. Surface Roughness (Ra Value)

Both methods can achieve very low Ra values, but their capabilities and limitations differ:

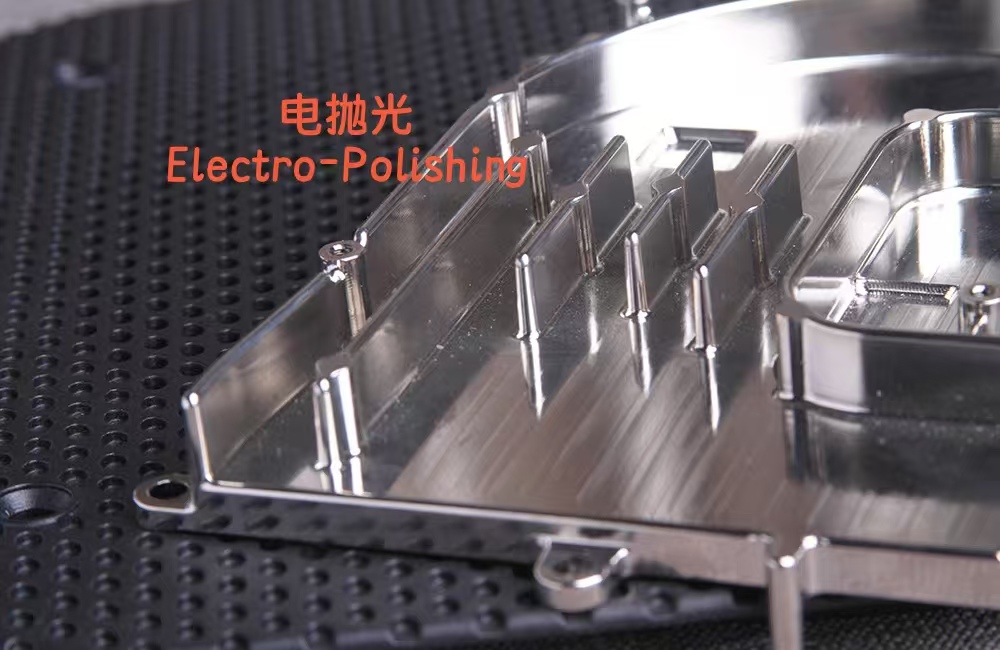

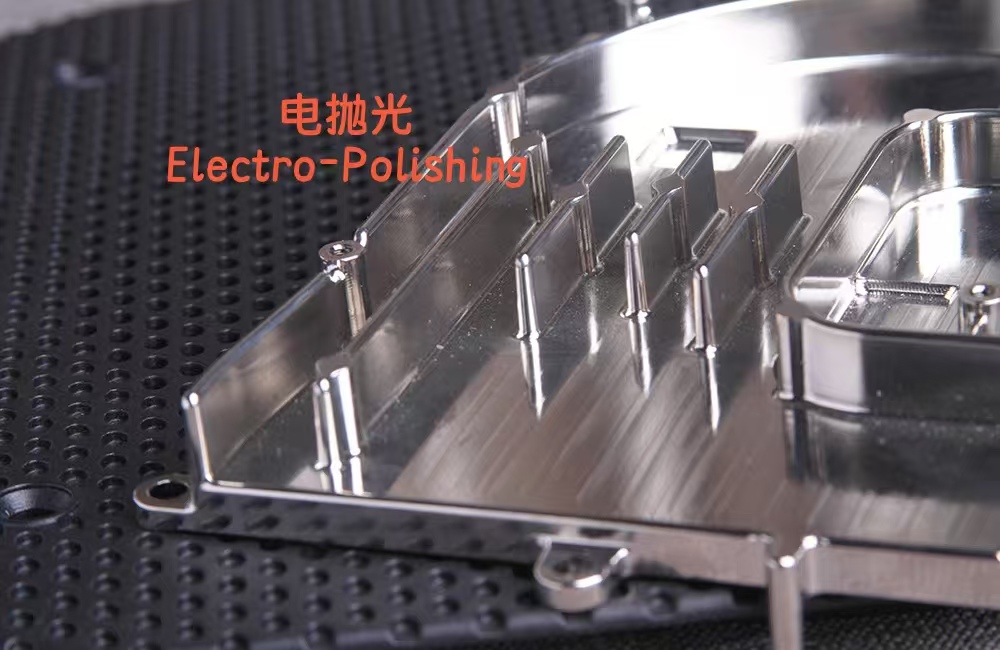

- Electropolishing: Produces extremely smooth surfaces with Ra values typically ranging from 0.02-0.1 μm (even lower for high-purity metals like stainless steel). The electrochemical dissolution process removes surface peaks uniformly, creating a "mirror-like" finish without directional patterns. It excels at reducing roughness in hard-to-reach areas (e.g., crevices, threads) as effectively as on flat surfaces.

- Mechanical Polishing: Can also reach low Ra values (0.01-0.1 μm) with fine abrasives (e.g., diamond pastes, colloidal silica), but this requires meticulous, multi-step processing (from coarse grits to ultra-fine). However, it may leave subtle directional "lay" patterns (from abrasive movement) or micro-scratches, especially on complex geometries where tool access is limited.

. Surface Integrity & Microstructure

- Electropolishing:

- Creates a stress-free surface. By dissolving material through anodic reaction, it eliminates surface defects like micro-cracks, tool marks, or residual stresses from prior machining (e.g., grinding or stamping).

- Refines the surface microstructure: Removes deformed surface layers (a common byproduct of mechanical processing) and exposes a more uniform, pure metal matrix, which enhances corrosion resistance (critical for metals like stainless steel).

- Mechanical Polishing:

- May introduce residual compressive stress due to physical abrasion. While this can improve fatigue resistance in some cases, it can also trap abrasive particles or cause micro-plastic deformation, leading to uneven wear over time.

- Leaves a thin "work-hardened" layer on the surface, which may alter the material’s chemical reactivity (e.g., reducing corrosion resistance in stainless steel if not properly cleaned).

. Uniformity Across Complex Geometries

- Electropolishing: Shines here. The electrolyte penetrates all surfaces-including holes, grooves, internal channels, and intricate contours-ensuring consistent polishing across the entire part. This is impossible with mechanical methods, which struggle to reach recessed areas, often leaving them rougher or unpolished.

- Mechanical Polishing: Relies on direct contact with abrasives, so flat, convex, or simple shapes (e.g., sheets, rods) get uniform results. But complex parts (e.g., medical implants with slots, aerospace components with cavities) will have uneven finishes-smooth on accessible areas, rough in hidden spots.

. Defect Resistance & Functional Performance

- Electropolishing: Produces a passive, low-porosity surface (especially on stainless steel) by removing iron-rich surface layers and enriching chromium, which drastically improves corrosion and chemical resistance. This makes it ideal for parts in harsh environments (e.g., chemical processing, marine applications) or where sterility is critical (e.g., medical tools, food-grade equipment).

- Mechanical Polishing: While it creates a smooth surface, the micro-abrasions can act as "nucleation sites" for corrosion or bacterial growth if not sealed. It’s better for decorative purposes (e.g., automotive trim, jewelry) where aesthetics matter more than long-term chemical resistance.

How to Choose Based on Surface Quality Needs

- Prioritize uniformity on complex parts +corrosion resistance: Electropolishing is superior.

- Need a high-gloss, decorative finish on simple shapes: Mechanical polishing works well (and is often cheaper for small batches).

- Require stress-free surfaces for critical applications (e.g., aerospace, medical): Electropolishing avoids residual stress.

- Working with non-conductive materials (plastics, ceramics): Mechanical polishing is the only option, as electropolishing requires conductivity.

In short, electropolishing delivers more consistent, durable, and functionally superior surface finishes-especially for complex, high-performance parts-while mechanical polishing is simpler and more cost-effective for straightforward, aesthetic-focused applications.

. Surface Roughness (Ra Value)

Both methods can achieve very low Ra values, but their capabilities and limitations differ:

- Electropolishing: Produces extremely smooth surfaces with Ra values typically ranging from 0.02-0.1 μm (even lower for high-purity metals like stainless steel). The electrochemical dissolution process removes surface peaks uniformly, creating a "mirror-like" finish without directional patterns. It excels at reducing roughness in hard-to-reach areas (e.g., crevices, threads) as effectively as on flat surfaces.

- Mechanical Polishing: Can also reach low Ra values (0.01-0.1 μm) with fine abrasives (e.g., diamond pastes, colloidal silica), but this requires meticulous, multi-step processing (from coarse grits to ultra-fine). However, it may leave subtle directional "lay" patterns (from abrasive movement) or micro-scratches, especially on complex geometries where tool access is limited.

. Surface Integrity & Microstructure

- Electropolishing:

- Creates a stress-free surface. By dissolving material through anodic reaction, it eliminates surface defects like micro-cracks, tool marks, or residual stresses from prior machining (e.g., grinding or stamping).

- Refines the surface microstructure: Removes deformed surface layers (a common byproduct of mechanical processing) and exposes a more uniform, pure metal matrix, which enhances corrosion resistance (critical for metals like stainless steel).

- Mechanical Polishing:

- May introduce residual compressive stress due to physical abrasion. While this can improve fatigue resistance in some cases, it can also trap abrasive particles or cause micro-plastic deformation, leading to uneven wear over time.

- Leaves a thin "work-hardened" layer on the surface, which may alter the material’s chemical reactivity (e.g., reducing corrosion resistance in stainless steel if not properly cleaned).

. Uniformity Across Complex Geometries

- Electropolishing: Shines here. The electrolyte penetrates all surfaces-including holes, grooves, internal channels, and intricate contours-ensuring consistent polishing across the entire part. This is impossible with mechanical methods, which struggle to reach recessed areas, often leaving them rougher or unpolished.

- Mechanical Polishing: Relies on direct contact with abrasives, so flat, convex, or simple shapes (e.g., sheets, rods) get uniform results. But complex parts (e.g., medical implants with slots, aerospace components with cavities) will have uneven finishes-smooth on accessible areas, rough in hidden spots.

. Defect Resistance & Functional Performance

- Electropolishing: Produces a passive, low-porosity surface (especially on stainless steel) by removing iron-rich surface layers and enriching chromium, which drastically improves corrosion and chemical resistance. This makes it ideal for parts in harsh environments (e.g., chemical processing, marine applications) or where sterility is critical (e.g., medical tools, food-grade equipment).

- Mechanical Polishing: While it creates a smooth surface, the micro-abrasions can act as "nucleation sites" for corrosion or bacterial growth if not sealed. It’s better for decorative purposes (e.g., automotive trim, jewelry) where aesthetics matter more than long-term chemical resistance.

How to Choose Based on Surface Quality Needs

- Prioritize uniformity on complex parts +corrosion resistance: Electropolishing is superior.

- Need a high-gloss, decorative finish on simple shapes: Mechanical polishing works well (and is often cheaper for small batches).

- Require stress-free surfaces for critical applications (e.g., aerospace, medical): Electropolishing avoids residual stress.

- Working with non-conductive materials (plastics, ceramics): Mechanical polishing is the only option, as electropolishing requires conductivity.

In short, electropolishing delivers more consistent, durable, and functionally superior surface finishes-especially for complex, high-performance parts-while mechanical polishing is simpler and more cost-effective for straightforward, aesthetic-focused applications.