News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > News

CNC Machined Parts: Quality Assurance for Every Project

Add Time:2025-07-31

CNC machined parts require strict quality assurance (QA) processes to ensure they meet design specifications and performance requirements. Here's a breakdown of key QA measures for every project:

. Design and Pre-Production Checks

- Design Review: Verify CAD models and technical drawings for accuracy (tolerances, dimensions, material specifications) to avoid errors before machining.

- Material Inspection: Confirm raw materials (e.g., metals, plastics) meet standards via certificates (e.g., material test reports) and physical checks (hardness, composition).

- Tooling Validation: Ensure cutting tools, fixtures, and CNC programs are calibrated and tested with sample runs to prevent tool wear or misalignment issues.

. In-Process Quality Control

. In-Process Quality Control

- Real-Time Monitoring: Use sensors and CNC software to track parameters like cutting speed, feed rate, and temperature, flagging deviations instantly.

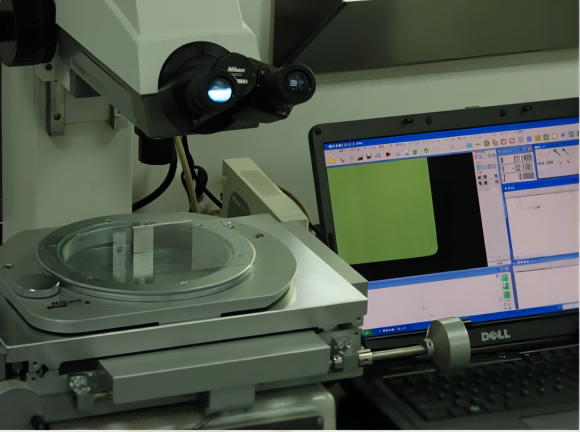

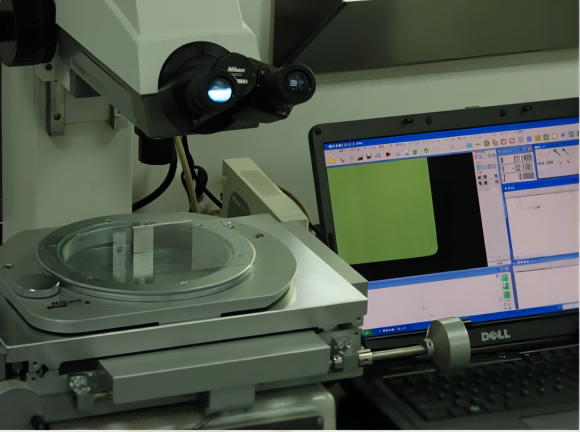

- Dimensional Checks: Regularly measure critical features during production using tools like calipers, micrometers, or coordinate measuring machines (CMMs) to maintain tolerances.

- Visual Inspections: Check for surface defects (scratches, burrs) or irregularities that may affect functionality.

. Post-Production Testing

- Material Integrity Checks: Use methods like ultrasonic testing or X-ray inspection to detect internal flaws (cracks, porosity) in critical parts.

. Documentation and Traceability

- Maintain detailed records of inspections, material batches, and production data to trace issues back to their source.

- Certify compliance with industry standards (e.g., ISO 9001, AS9100 for aerospace) through audit-ready documentation.

By integrating these steps, manufacturers ensure CNC machined parts are consistent, reliable, and meet project-specific quality goals.

. Design and Pre-Production Checks

- Design Review: Verify CAD models and technical drawings for accuracy (tolerances, dimensions, material specifications) to avoid errors before machining.

- Material Inspection: Confirm raw materials (e.g., metals, plastics) meet standards via certificates (e.g., material test reports) and physical checks (hardness, composition).

- Tooling Validation: Ensure cutting tools, fixtures, and CNC programs are calibrated and tested with sample runs to prevent tool wear or misalignment issues.

- Real-Time Monitoring: Use sensors and CNC software to track parameters like cutting speed, feed rate, and temperature, flagging deviations instantly.

- Dimensional Checks: Regularly measure critical features during production using tools like calipers, micrometers, or coordinate measuring machines (CMMs) to maintain tolerances.

- Visual Inspections: Check for surface defects (scratches, burrs) or irregularities that may affect functionality.

. Post-Production Testing

- Final Dimensional Verification: Conduct full inspections of finished parts against drawings, using advanced tools (e.g., 3D scanners) for complex geometries.

- Functional Testing: Validate performance under real-world conditions (e.g., load testing for structural parts, pressure testing for fluid components).- Material Integrity Checks: Use methods like ultrasonic testing or X-ray inspection to detect internal flaws (cracks, porosity) in critical parts.

. Documentation and Traceability

- Maintain detailed records of inspections, material batches, and production data to trace issues back to their source.

- Certify compliance with industry standards (e.g., ISO 9001, AS9100 for aerospace) through audit-ready documentation.

By integrating these steps, manufacturers ensure CNC machined parts are consistent, reliable, and meet project-specific quality goals.