- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

In CNC machining, the choice of surface treatment process directly affects the functionality, aesthetics and durability of parts. The following are common surface treatment technologies and their characteristics:

First, mechanical surface treatment

. SandblastingMedium: glass beads (80-400 mesh), alumina, silicon carbide

Effect: Matte texture (Ra1.6-6.3μm), eliminating slight finish marks

Applications: Aluminum alloy housing, medical equipment

. Polishing

Mirror polishing: Diamond grinding paste (Ra≤0.05μm) for optical partsVibration polishing: Batch deburring of ceramic abrasives, suitable for small complex parts

. Lapping

Precision surface grinding: monocrystalline silicon (flatness ≤0.001mm)Superfinishing: Reduce surface corrugation (such as automotive camshafts)

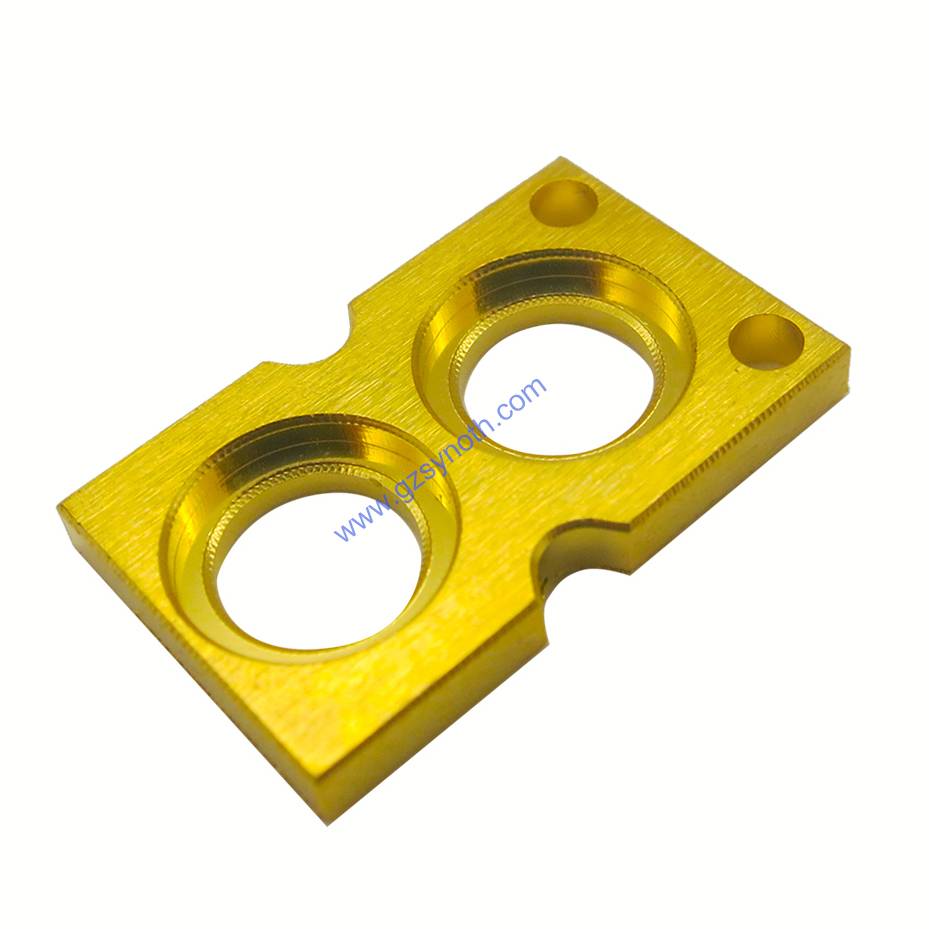

Second, chemical/electrochemical treatment

. Anodizing

Hard anodizing: Film thickness 50-100μm (HV≥800) for aviation components

Color anodizing: coloring by electrolysis (e.g., iPhone aluminum body)

. Passivation

Stainless steel passivation: nitric/citric acid removes free iron and improves corrosion resistance

Electrolytic polishing: micro-levelling (Ra reduction by 50%+), suitable for food grade equipment

. Electroless Plating

Electroless nickel plating: uniform coating (hardness HV500-700), repair wear partsThird, coating technology

PVD coating (physical vapor deposition)

TiN/TiAlN coating: Tool surface hardness HV2000-3000DLC diamond-like coating: friction coefficient < 0.1 (automobile piston ring)

. Thermal Spray

Plasma spraying: Zirconia thermal barrier coating (turbine blade)Supersonic Flame spraying (HVOF) : WC-Co abrasion resistant coating

. Special function processing

.Laser surface treatment

Laser cladding: Repair of high value parts (e.g. die cutting edge)

Laser Texture: Custom micron surface patterns

. Micro Arc Oxidation (MAO)

Magnesium alloy treatment: in situ formation of ceramic film (corrosion resistance improved by 10 times). Dacromet

.Chromium-free zinc-aluminum coating: Salt spray resistance 1000h+ (automotive chassis parts)

. Composite Technology (cutting-edge technology)

Nano composite plating: SiC/Al₂O₃ nanoparticles are added to enhance the coating

Ion implantation: Surface alloying (such as medical titanium alloy antibacterial treatment)

Cold spray additive manufacturing: low temperature deposition of copper/aluminum conductive layer